- Home

- Products

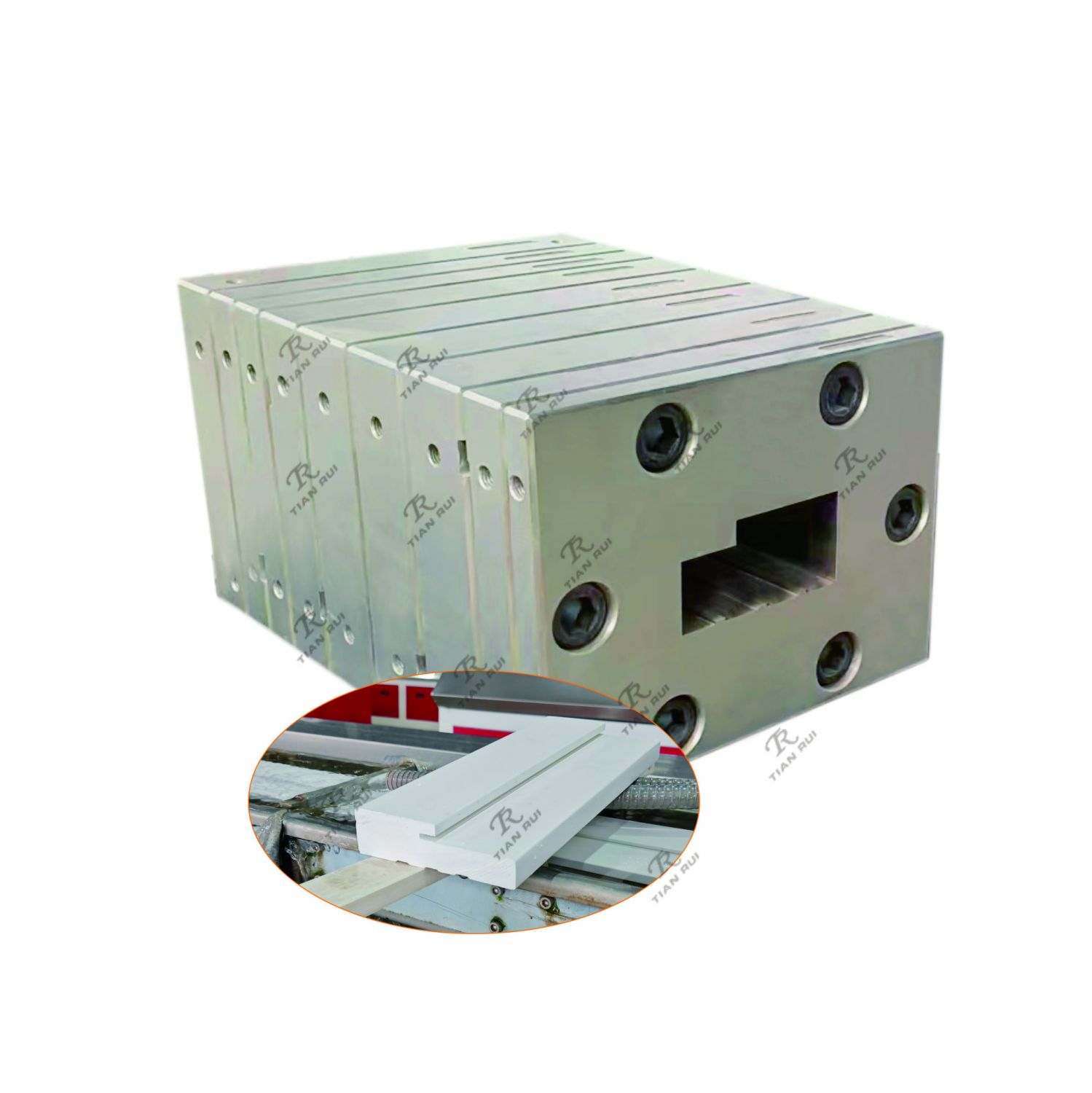

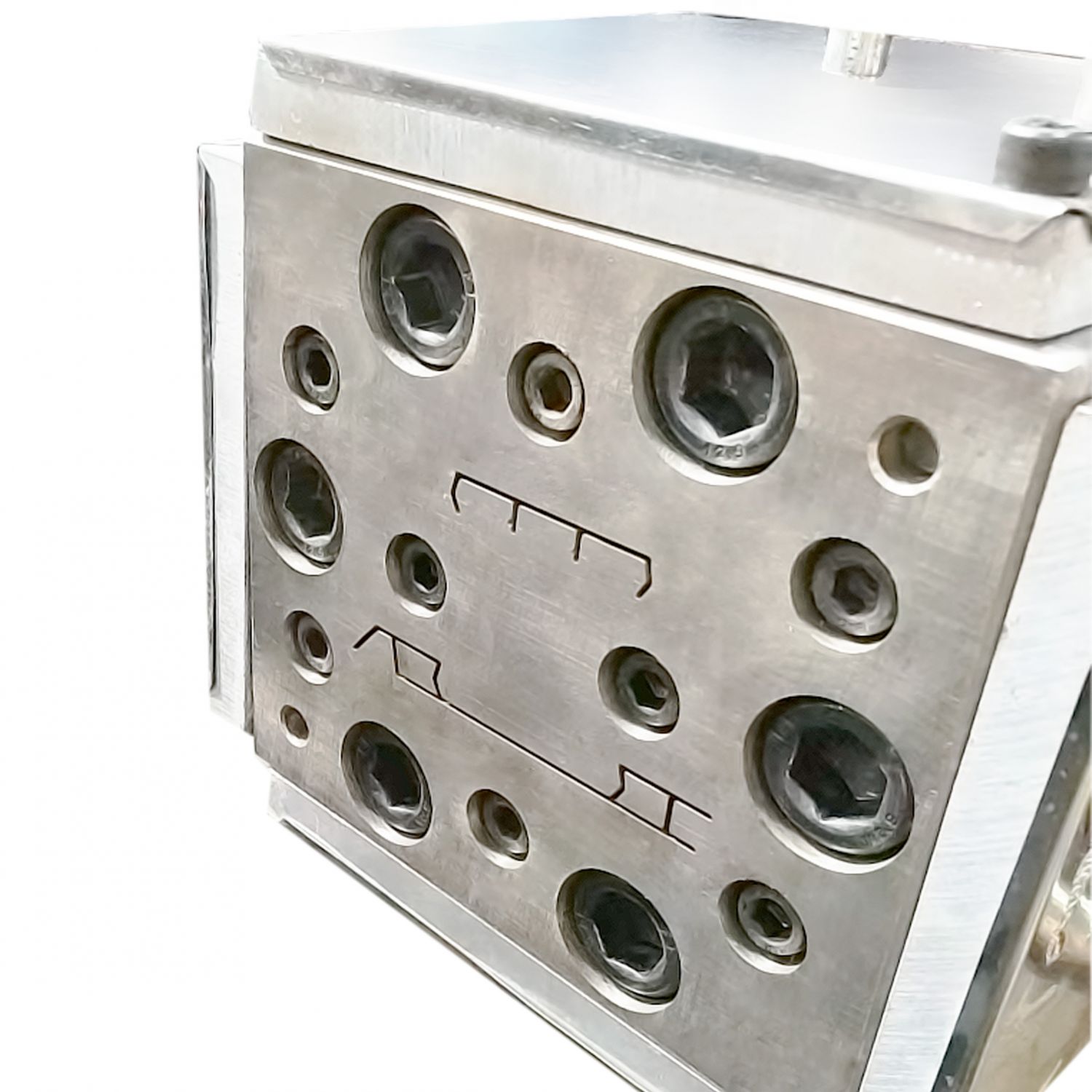

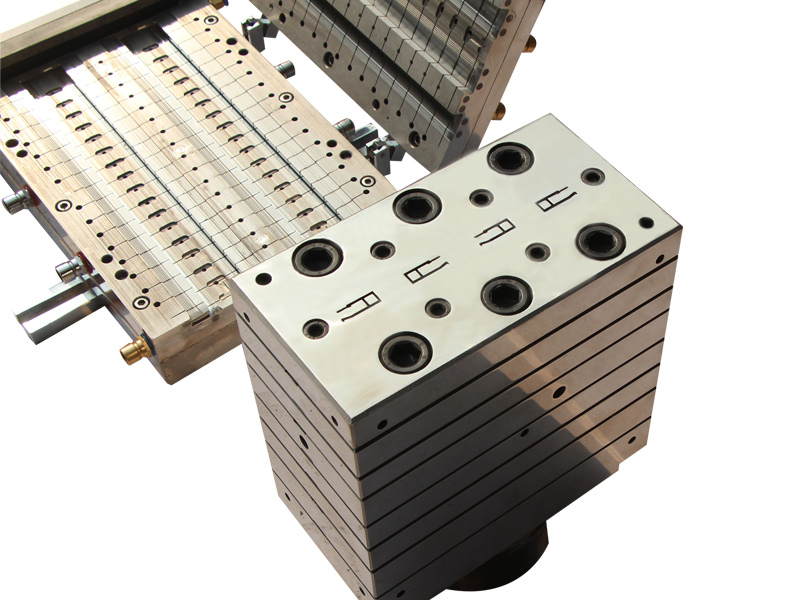

- Wide Panel Mould

- Customized UPVC Profile Extrusion Tooling

- Hot Sale PP Profile Extrusion Tooling

- Superior Quality PVC ceiling extrusion mould

- PVC WPC Door Panel Extrusion mould

- Wall Panel Extrusion Tooling

- PP Profile Tool Shed Extrusion Mould

- Wall Panel Extrusion Mould

- UPVC Tile Extrusion Mould

- WPC Door Extrusion mould

- PVC ceiling extrusion mould For Ceiling Panel extrusion die

- Tile Extrusion Mold Die For PVC ABS Roof Tile Board Custom Extrusion

- Building board Profile die tooling and Extrusion Line Mould

- PVC Ceil Molding For Ceiling Panel Customized Plastic Molding Machine

- WPC Decorative plates extrusion molding environmental protection material mould for indoor

- PVC Wood Wall Panel Extrusion Die Mould Wallboard making machine

- 100mm 200mm WPC Door panel Molding Machine Profile Extrusion Mould

- Co-Extrusion Die Pvc baseboard Molding Machine door Frame Plastic Extrusion Mould

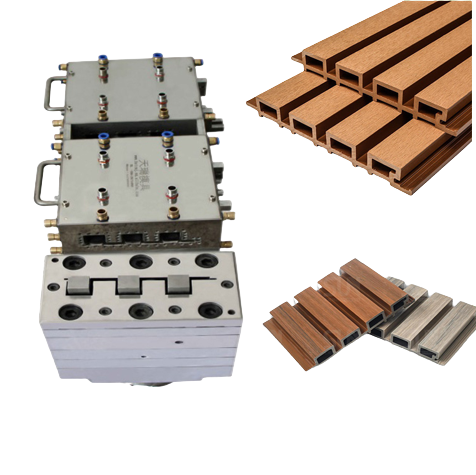

- WPC Floor Panel Extrusion Mold/PVC WPC Floor Board Mould machine /tool

- Hot Selling mold Price Customized 300mm PVC Wide Plate Extrusion Mould

- WPC mould/mold/die/tools, extrusion mould for handrail, PVC PE WPC handrail mouldings

- UPVC Wide Panel Mould

- UPVC Windowsill Mould

- Wide Wall Siding Mould

- Building Template Mould

- PE + wood powder WPC mould

- Hot Sale PE Decking extrusion mould

- PE WPC Wall Panel Extrusion Mold

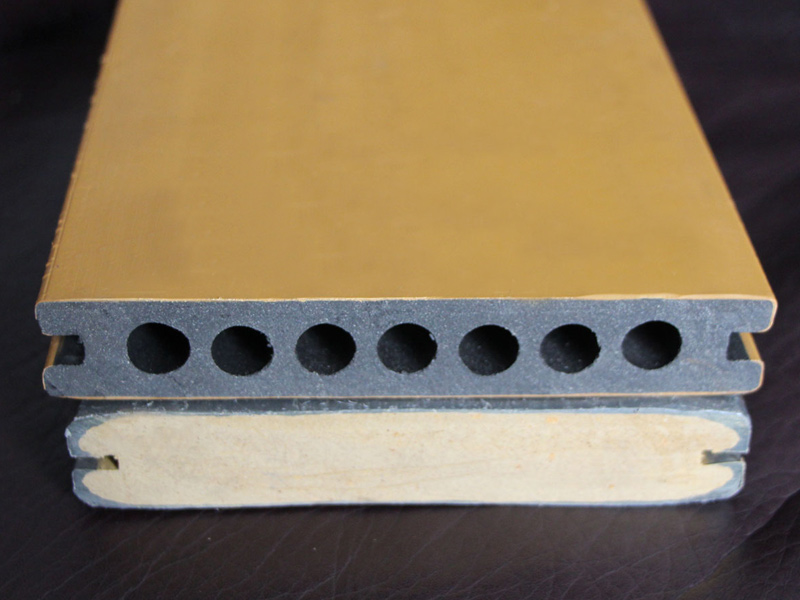

- PE WPC decking floor panel plastic die extrusion

- PVC/PE+WPC Extrusion Mould

- Profile Extrusion Mould manufacture for PE WPC wood column

- Profile Extrusion Mould manufacture for PE WPC wood column

- China golden supplier custom wpc garden outdoor column extrusion molds

- 3Cr13 WPC PE decking embossing floor plate plastic profile plastic die extrusion

- Decking Die Head WPC Wood hardwood strip Plastic Extrusion Mould

- Decking Die Head WPC Wood hardwood strip Plastic Extrusion Mould

- PE trash can die Tools With High Efficiency Profile Extrusion Mould

- High Quality profile die and mould PE door panel extrusion

- Wood Plastic Wall Panel Extrusion Die Mould Wallboard Making Tooling

- Low Price WPC Extrusion Mold Fence Moulding Handrail Mould Making Machine

- Co-Extrusion Mould Die Head for WPC Stand Column Extrusion Molding

- High Quality mold Price PVC WPC window sill Extrusion die Mould Customized

- PE WPC Square Wood Mould

- PE WPC Handrail Mould

- PE WPC Wall Panel Mould

- PE WPC Chair Strip / Lath Mould

- PE WPC Column Mould

- PE WPC Profile Mould

- Mould For WPC Warpage

- PE WPC Keel Mould

- PVC + wood powder WPC mould

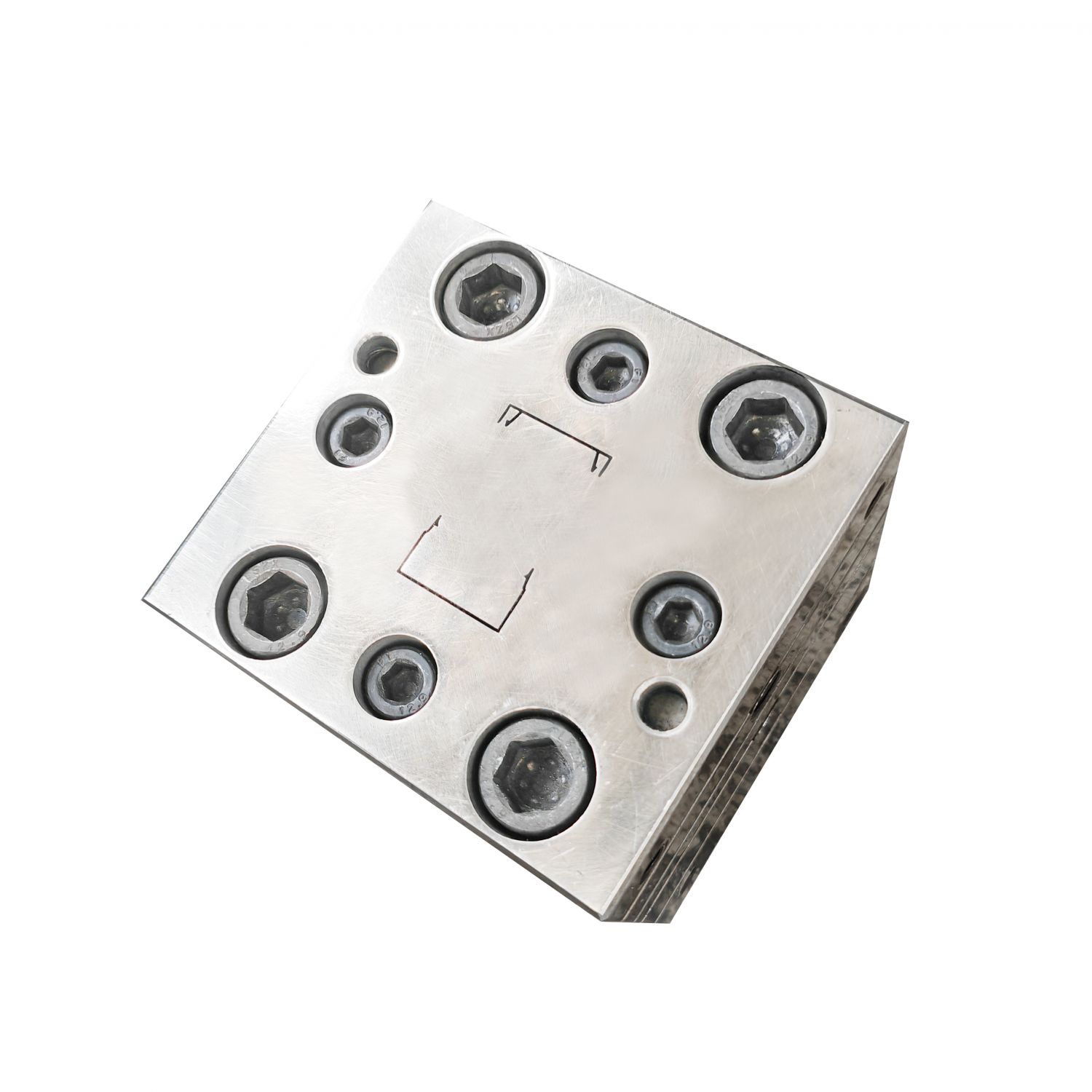

- WPC Architrave Door frame extrusion Tool Extrusion Mould

- PVC WPC Door frame Extrusion Die

- 3cr17 WPC Door frame Extrusion Tooling PVC

- WPC Door frame Mold extrusion tooling

- Outdoor decking extrusion mould PE based WPC keel mold

- PVC WPC Decorative Embossing Co-extrusion Wall Panel Indoor Panel Extrusion Mold Die

- plastic wood extrusion die Molding WPC Wall board Making Tooling

- WPC Mold to profile WPC extrusion die head for handrail

- Door frame Molding Door stop extrusion mould/tooling for PVC WPC foam frame

- Extrusion molding plastic extrusion PVC ceiling mould 3Cr13 3Cr17 pvc wall panel mold

- Customized cheap price PVC wood plastic balcony railing fence extrusion mould

- WPC joist decking wood plastic extrusion mould composite joist beam for outdoor flooring

- WPC extrusion mold foaming Wood Plastic Decking Mould Extruder Mold

- WPC extrusion decorative lines WPC door line extrusion mold foaming

- Decorative 3Cr13 3Cr17 PVC WPC Wall Panel Board wpc extrusion plastic wood extrusion die head

- Hot Selling PVC plastic profile plastic mouldings

- Molding frame extrusion mould/tooling for PVC WPC foam frame

- China steel 3CR17 Decoration Line WPC profiles extrusion mould

- Co-Extrusion Mould Die for WPC Square Stand Column Fence Series Extrusion Mold

- WPC Door Extrusion Door Sheet Mould Door Panel Molding

- WPC Wall Panel Decking Wood Molding Extrusion Moulding

- Composite Wood Plastic Keel Extrusion Mould For WPC Indoor/Floor Paving Fixture Moding

- Plastic Extrusion Tooling PVC WPC door frame extrusion mould

- Wood Plastic WPC Decking Slat Extrusion Molding machine Tooling

- China Manufacturer PVC Plank fence extrusion mould deck promenade extruder fence making machine

- WPC Decking Mould Die For Baseboard Molding Machine

- Door Frame plastic molding Pvc wpc Dies Moulding Plastic Extrusion Mould

- https://www.alibaba.com/product-detail/Double-Out-Panel-Extrusion-Mould-Die_1600627254691.html?spm=a2747.manage.0.0.215471d2ignzn6

- PVC Laminating Machine For Ceiling Panel Making Machine Extrusion Line

- High Quality pvc wood cabinet board plastic extrusion die mould

- Great Wall Panel Wavy Borad WPC Extrusion Die mould for Decorative Board

- Ex-factory Price Composite PVC Foaming Board Extrusion Mold Plastic Extruder Making Machine

- PVC WPC Door Panel Mould

- PVC WPC Great Wall Panel Mould

- PVC WPC Corner Line Mould

- PVC WPC decoration panel mould

- PVC WPC Floor Mould

- PVC WPC Square Wood Mould

- PVC WPC Door Frame Mould

- UPVC Window and Door Profile Mould

- Hot Sale UPVC Door Panel Extrusion Mold

- PVC Window and Door Extrusion Tooling

- UPVC Window&Door Mold Extrusion Dies

- UPVC Window&Door Profiles Extrusion Mould

- Window and Door Profile Mould

- UPVC Profiles extruder Die Window Extrusion Mould

- UPVC Door panel Mould PVC plate extrusion Die

- UPVC profiles Co-extrusion Mould For Window extrusion machine

- UPVC window molds PVC Embossing extrusion mould Machine

- Plastic Profile Extrusion Tooling/Extrusion Mould Maker For Door Frame and Window

- Plastic Extrusion Mould Window Frame Profiles PVC Profile molds

- Sliding Upvc plastic window moulding High-speed Co-extrusion Die

- Plastic Mould Door Panel Extrusion Die For WPC Extrusion Machine

- Interior Decorating PE wood keel profile plastic mould

- Hot mold for soft and hard plastic layer co-extrusion mould

- Plastic Molding Door For PVC Door Panel Extrusion Making Mould Machine

- China Customized PVC Door Stop Molding WPC Door frame extrusion Die

- PVC Windows Die UPVC Window Sill Panel Die Mould Makers

- Plastic mould supplier Soft and Hard PVC Co-extrusion Extrusion Mold

- Color Soft-rigid Co-extrusion Mold PVC Rubber Scrip Molding Die

- New Product Custom UPVC Window and Door Profile Extrusion Mould

- New Product Custom UPVC Window Sill/Panel Profile Extrusion Mould

- Chinese Supplier Co-extrusion Foaming Wood-like wpc outdoor decking Process Plastic Extrusion Mould

- UPVC PVC profile extrusion window mould and window frame moulding design and custom

- Co-extrusion die Head For PVC Door and Window Molding Machine

- Plastic PVC WPC extrusion mold For Doorframe Door lining moulding

- Die Head Customized Cheap extrusion mold Price with PVC material for window frame

- UPVC door and window fan extrusion tooling mould products maker

- OEM customize PVC door and window Co-Extrusion Mold/Moulding making machine

- Window and Door Profile High Speed Mould

- Window and Door Profile Rolled Mould

- Window and Door Profile Co-extrusion Mould

- Pipe Mould

- Hot Sale Customized Drainage Pipe Extrusion Mold

- Plastic Die Extrusion supplier for Round tube/communication tube

- Extrusion Mold Plastic mouldings supplier for Round tube/communication tube

- China Customized Mould Drainage Pipe Molding PVC Pipe Line Tooling Machine

- Pipe Extrusion molding Drainage Water PVC Pipe Making Machine

- PVC Multi-hole Pipe Extrusion Mold For Wire Pipe Extrusion Line

- Hot sale PE Pipe Co-extrusion Mould plastic mould manufactur direct sales

- PVC Mould Manufacturer Winding Pipe Extrusion Mold Making Machine

- customized tube mould SRWPE drainage water PVC pipe production line making machine

- Drain Pipe Mould

- Communication Pipe Mould Series

- Radome Mould

- Winding Pipe Mould

- Plastic Steel Co-extrusion Mould

- Color Co-extrusion/ Multi-material Co-extrusion Mould

- China Make Superior Quality PMMA/PC Lampshade Extrusion Mould

- Plastic Co-extrusion Tooling for Price Tag PVC Profile Extrusion Mold

- Price Tag Co-extrusion Mould PVC Profile Extrusion Tool

- Tianrui Mould PMMA PC Lampshade Extruder Die Co-Extrusion Mould

- Plastic Co-extrusion Mould die for extruder PVC profile molds

- Plasthetics Mould Rubber Waterstop Extrusion Tool flexible PVC die

- Soft PVC Extrusion Mould Plastic Hard-soft Co-extrusion Die Head

- Factory Price Soft-hard Surface Layer Customized Pvc Window Door Profile extrusion die head

- Soft PVC Mold Rubber Extrusion Mould Plastic Co-extrusion Die

- Composite Materials Extrusion Color Co-Extrusion Mold/Mouldings

- UPVC Window Frame Co-extrusion Mould For Window Profile Molding

- UPVC extrusion mould wpc pipe co-extrusion mould die

- Soft and hard co-extrusion UPVC window and door Plastic Extrusion Mould

- Plastic Mould Manufactur Multi-material Extrusion die For PVC Door and Window Co-extrusion line

- New Product Hot Sale WPC Co-extrusion Mouldings Extrusion Mold

- Window and Door Profile Co-extrusion Mould

- Steel Plastic Co-extrusion Mould

- Door Frame Co-extrusion Mould

- UPVC Profile Mould

- PVC Trunking Mould Hot Sale Extrusion Tooling

- UPVC Wall Panel Extrusion Tooling

- PVC Trunking Extrusion Mold Cable Duct Extruder Die

- PVC Baguette Extrusion Mould Seal Strip Extrusion Die

- PVC Skirting Line Mold Marble Base board Extrusion die

- UPVC Trunking Extrusion Mould cable duct mold

- UPVC Trunking Extrusion Mould

- Cooling Extrusion Mould

- UPVC Wall Panel Extrusion Mould

- Hydroponic plastic extrusion mould pvc water channel making machine

- PVC Baseboard Making Tool Marble Skirting For Plastic Extrusion Die

- Mold manufacturer PVC water channel plastic mould maker

- Single cavity pvc baseboard cover and bottom extrusion mould/tooling/die

- PVC Windows Mold Window Sill Panel extrusion Die

- PVC extruder moulding External hanging wall panel plastic die extrusion

- 3Cr13 extruder dies Molding PVC water channel plastic extrusion mould

- Hot sell high quality custom Plastic PVC antenna radome extrusion mould

- Multi Cavities Mold PVC Plastic Wiring Duct Cable Trunking die Mould Extruder

- Extruder dies for house Pvc water Pipe extrusion die Head mold plastic extrusion mould

- India Design PVC Rain Gutter Extruder mold extrusion tooling Mould

- Professional custom mold PVC extrusion profile for windows& door

- PVC Plastic Extrusion Mould Electrical Cable Trunking Profiles Mold for Sale

- PVC trunking die mould/cable channel extrusion tooling/UPVC Hydroponic plastic extrusion mould

- PVC Radome Plastic Profile Extrusion Mold

- PVC water channel plastic mould maker Molding manufacturer

- Custom PVC Molding Extrusion UPVC Profile Plastic Extrusion Profile Moulding

- Custom Extrusion PVC Profile Moldings Wire Trunking Die Mould

- PVC Decking Board Deck Panel Extrusion Molding

- upvc pvc wiring duct extrusion profile die and mould

- PVC Windows Die UPVC Window Sill Panel Die Mould Makers

- Low Price 60 70 80 Series Windows die Molding UPVC Profile Window Extrusion Mould

- PVC Baseboard Making Tool Skirting Extrusion Molding Machine For Skirting Making Machine

- Plastic Molding Tool For Ceiling Panel Extrusion Machine PVC Extrusion Machine

- Extrusion molding plastic extrusion PVC ceiling mould 3Cr13 3Cr17 pvc wall panel mold

- Extrusion Mold For Ceiling Panel Extrusion Machine PVC profile extrusion line

- PVC plastic mould manufacturer wiring duct outdoor decking profile extrusion mold

- Plastic Mouldings Marble Extrusion Die Head For PVC Profile Extrusion Line

- Gutter Mould

- Strip Mould

- Corner Line Mould

- Profile Mould

- Pvc Tile Mould

- UPVC Profile Mould

- Window Sill Extrusion Mould

- Plastic Marble Mould

- PVC Marble Extrusion Mould

- Multi-cavity High Speed Mould

- Customized High-Speed PVC Trunking Extrusion Tooling

- PVC Trunking High-speed Extrusion Mould Cable Duct Mold

- Polyamide Extrusion Mould Glass Fiber Extrusion Tool PA66

- Plastic Steel Decking extrusion die PVC Skirting Board Extrusion tool

- Embossing co-extrusion tool multi-material Co-extrusion Die Head

- PVC Multi-cavity High-speed Extrusion Mold For Plastic Molding Machine

- Flooring Tile Making Machine Double-Cavity Floor Panel Extrusion Mold

- Co-extrusion Extrusion Multi-cavity Extrusion Molding High Speed Die Head

- Two Cavities Gusset Mould

- Four Cavities Corner Mould

- Four Cavities Strip Mould

- Other Multi-cavity Moulds

- Foaming Mould

- PVC Decking Mould Foaming Board Skirting Extrusion Tooling PVC

- PVC Decking Mould Foaming Board Skirting Extrusion Tooling

- PS/PET/EVA Foam Extrusion Mould

- XPS Profile Two Cavities Plastic foaming Profile Extrusion Die Mold

- Hot Selling WPC wood foam frame Professional extrusion machine

- Ex-factory price PE PS EVA Foaming Board Extrusion Mold PVC Foaming Board Machine

- Cheap Wood Foam Mould For PVC Hollow Decking Extrusion Machine

- PVC Solid Skinning Foaming Board Mould

- PVC Foaming Photo Frame Extrusion Mould

- ABS, PP, PE, PC, PMMA Moulds

- PA6/PA66 Profile Extrusion Tooling

- ABS Extrusion Mould

- PA6/PA66 Profile Mould Polyamide Making Machine Fiberglass Extrusion Die Head

- PP Tool shed extrusion Tooling Panel Extruder Die

- PC Extrusion Mould

- ABS Extrusion Mould

- GlassFiber Pultrusion Dies for FRP Extrusion Mould

- PE Extrusion Tool Garden isolation belt Extrusion Mould

- PP plastic Used In Construction mold extrusion die Building plate plastic die extrusion

- PE Ocean pedal Floor Panel Extrusion die plastic profile mold

- PA66 extrusion mould polyamides fiber glass extruder die

- Plastic Tool Shed Mold PP Panel Garden House Extrusion machine Tool

- PMMA Lampshade extruder dies Lamp-chimney Extrusion Mould

- Die for extruder PA66 Profiles moulding plastic die extrusion plastic extrusion mould

- PP Wall Panel extrusion molding Wallboard extruder dies

- China Manufacturer Customized PC Lampshade Extrusion Mold

- Indoor Decorative Louver PC lampshade Extrusion Mold

- Profile extrusion machine line HDPE ocean Pedal plastic mould maker

- Tile Extrusion Mold Die For PVC ABS Roof Tile Board Custom Extrusion

- PE Wood Multi-cavity Floor Panel Mould WPC Floor extrusion die

- PE Wall Panel Pedal Wood Molding WPC Decking Die Mould

- Factory Manufacture PA66 strip Mold Machine Die Head Moulding

- AS, ABS profile mould

- PE Profile Mould

- PP Mould

- HDPE Extrusion Mould

- ABS Extrusion Die

- Production Machine

- HDPE/PP/PVC Double Wall Corrugated Pipe And Ribbed Pipe Extrusion Line

- Steel Reinforced Spiral Pipe Extrusion Line

- PE, PP, PVC And Wood Plate Extrusion Line

- PE,PP And Wood, PVC And Wood (Foamed) Panel Extrusion Line

- UPVC High Speed Profile & Foamed Profile Extrusion Line

- SJP Series Parallel Twin-Screw Extruder, Twin-Screw Extruder

- SJZ Series Conical Twin-Screw Extruder,Twin-Screw Extruder

- Profile Surface Coating Co-extruder,Coating Co-extruder

- SJZ Series Counter Rotation Conical Twin-screw Pelletizing Extrusion Line

- Single Layer Or Multi-Layer PP, PE Pipe Extrusion Die And PVC Pipe Extrusion Die

- Soft PVC Extrusion Mould

- Soft PVC Extrusion Tooling

- Soft PVC Profile Extrusion Mold co-extrusion Tooling PVC

- Soft PVC Extrusion Die Gasket co-extrusion Tooling

- Tianrui mould soft pvc plastic extrusion mould PVC mold

- Transparent Pipe soft pvc mold rubber extrusion mould

- Profile Die Head Extrusion Mould for Soft PVC strip

- soft pvc plastic extrusion mould

- Decorative profiles High Quality PVC Extrusion Mold

- Plastic mould manufacturer Soft and Hard PVC Co-extrusion Extrusion Mold

- Design and custom Soft PVC profile extrusion mouldings

- Soft PVC Extrusion Mould

- Wide Panel Mould

- About

- Case

- News

- faq

- Contact

E-mail :

E-mail :

.jpg)

E-mail:

E-mail:

_200x150.jpg)